STEEL INDUSTRY ACCESSORIES

Galvanized/plastic coated B40 mesh

Introduction: Looking for durable and versatile mesh solutions for your construction or industrial projects? Look no further than our Galvanized/Plastic Coated B40 Mesh. This high-quality mesh is designed to meet your specific needs, providing strength, corrosion resistance, and longevity. Whether you're working on concrete reinforcement, fencing, or other applications, our B40 mesh is the perfect choice.

Key Features:

Galvanized and Plastic Coated: Our B40 mesh is not only galvanized for corrosion resistance but also coated with plastic to enhance durability and protect against the elements. This dual protection ensures a longer lifespan and reduces maintenance costs.

High Tensile Strength: The B40 designation indicates the mesh's strength. With a B40 rating, you can trust that this mesh offers excellent tensile strength, making it suitable for a wide range of applications, including concrete reinforcement.

Versatile Applications: This mesh is incredibly versatile. It can be used in concrete slab reinforcement, as fencing, or in any application where robust and corrosion-resistant mesh is required.

Easy to Work With: Our Galvanized/Plastic Coated B40 Mesh is easy to cut and shape, allowing for efficient installation in various projects. It's the ideal choice for contractors and builders looking to streamline their work.

Long-Lasting: Thanks to its galvanized and plastic coating, this mesh can withstand harsh environmental conditions, ensuring it remains in excellent condition for many years.

Applications:

Concrete Reinforcement: B40 mesh is widely used to reinforce concrete structures, such as slabs, walkways, and foundations, improving their load-bearing capacity and longevity.

Fencing: Its strength and corrosion resistance make it an excellent choice for fencing, providing security and durability.

Industrial and Construction: B40 mesh is suitable for industrial applications, including filtration, storage, and safety barriers, due to its robust construction.

Specifications:

Mesh Size: Our B40 mesh is available in various mesh sizes to suit different project requirements.

Roll Length and Width: Customizable options are available to ensure you get the right amount for your project.

Why Choose Us:

Quality Assurance: Our Galvanized/Plastic Coated B40 Mesh is manufactured to the highest quality standards, ensuring reliability and performance.

Custom Solutions: We understand that every project is unique. That's why we offer customizable options to meet your specific needs.

Competitive Pricing: We offer competitive pricing without compromising on quality, making our B40 mesh an economical choice for your projects.

Expert Support: Our team of experts is ready to assist you with product selection, installation guidance, and any questions you may have.

Order Your Galvanized/Plastic Coated B40 Mesh Today:

Enhance the strength and durability of your projects with our Galvanized/Plastic Coated B40 Mesh. Whether it's for concrete reinforcement, fencing, or any other application, you can count on the quality and performance of our mesh. Contact us today to discuss your requirements, request a quote, and place your order. We're here to help you succeed in your construction and industrial endeavors.

#ConstructionMesh

#IndustrialSolutions

#GalvanizedB40

#MeshStrength

#CorrosionResistance

#LongLastingMesh

#VersatileApplications

#ConcreteReinforcement

#FencingSolution

#IndustrialMesh

#DurableConstruction

#EasyInstallation

#CustomMeshOptions

#CompetitivePricing

#QualityAssurance

#ExpertSupport

#B40Rating

#RobustMesh

#MeshDurability

CONSTRUCTION OF WELDING NAILS (ANTI-CUT NAILS)

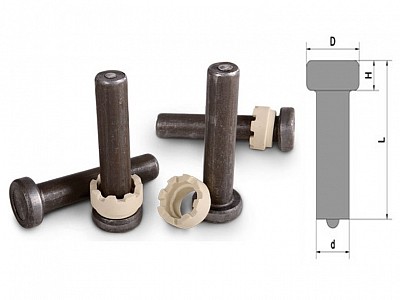

In addition to decking sheets, steel mesh, concrete..., welded anti-shear nails also play an important role in constituting the Steel - Concrete composite floor system.

Welded nails, also known as anti-shear nails, are composed of 3 main parts: nail cap, nail body and weld bead. Welding beads, also known as arc beads or primer beads, are small beads made from a special material with the purpose of easily melting when starting welding.

Thanks to that, the construction of welding nails becomes easier. In addition, the welding nails are also equipped with an external ceramic ring to prevent the arc from spreading widely and shooting upward.

Thanks to this detail, the welder is not blinded, the arc does not cause burns, the weld is full and beautiful without the need to use any welding rods or other welding additives.

1. Uses of welded nails (anti-shear nails):

- Welding nails are commonly used in steel structures of factories, bridges and roads. In fact, welded nails are specifically used in roofing and deck construction.

- In the Deck system: Welded nails have the effect of connecting Deck panels with steel beams and preventing vertical slippage for concrete floor blocks. . Thanks to that, the factory steel frame system - Deck panels

- Concrete are bonded together into a unified system.

- Anti-shear welded nails are also widely used in the construction of overpasses and steel bridges, and are now widely used. to build overpasses and pedestrian overpasses in the inner city. In steel bridge construction, shear-resistant welded nails promote the use of connecting concrete and steel frame structures.

2. Welded Nails (Anti-shear Nails) construction service:

Construction of anti-shear welded nails uses the welding construction method using an arc welding machine, this is for the purpose of welding anti-shear welded nails connecting corrugated iron and steel beams. Of course, the ultimate goal is to create a bond to keep the fixed concrete floor from sliding out of its original position and to prevent cracking between the two surfaces.

3. Steps to install welded nails (anti-shear nails) at the construction site:

Step 1: Prepare materials and equipment including: Welding nail - Ceramic ring; Arc welding apparatus; 3-phase power source; Wire; Transport vehicle...

Step 2: Mark the position to be welded, place the welding stud - ceramic ring in the position to be welded.

Step 3: Attach the anti-cut welding stud to the arc welding gun.

Step 4: Hold down the welding gun, Activating a large current flowing in the welding stud will create high temperatures concentrated inside the ceramic gasket, creating a large amount of heat that will melt the steel. It is the melting that creates the connection of the shear weld stud and the steel beam.

Step 5: Remove the ceramic ring and check the weld quality.

4. Quote for construction services of welding nails (anti-shear nails) at the construction site:

The price of welding nails depends on many factors that vary according to the characteristics of each project such as: Specifications of welded nails, location, project characteristics, 3-phase power source...

The productivity of welding nails at an average project is The average number is about 800-1,000 pieces/day. When you need to use anti-cut welding nails, please contact the Company directly to receive free consultation on using the service and get the best quote. .

#WeldedNails

#AntiShearConstruction

#SteelConcreteComposite

#ConstructionServices

#DeckSystem

#SteelStructures

#FactoryConstruction

#BridgeConstruction

#OverpassConstruction

#SteelBridges

#ArcWelding

#ConstructionMethods

#ConcreteFloor

#ConstructionTips

#WeldingTechnology

#WeldedNailsUsage

#ConstructionSteps

#WeldingQuality

#ProjectQuotation

#FreeConsultation

DECKING FLOORS

DECKING FLOORS

Definition

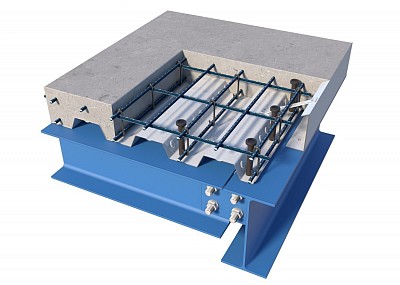

Decking floor is a steel sheet floor connected to a steel beam structure using welded studs. The deck sheet is structured as a corrugated galvanized steel sheet, welded onto a round steel beam with a triangular cross-section.

Decking floors are manufactured in a high-tech factory. This type of floor serves as a substitute for formwork without the need for supports. When combined with reinforced concrete flooring, it accelerates the construction progress.

Structure of Decking Floor

Deck Sheet: Replaces formwork during construction and contributes to load-bearing with the reinforced concrete floor during use. Common thicknesses are 0.75mm, 0.95mm, and 1.15mm.

Shear Studs: Connect the decking floor to the steel beam system and withstand cutting forces in the floor. In civil projects, M16x100 and M19x150 shear studs are commonly used.

Steel Mesh Floor: A layer of steel reinforcement woven together according to technical standards. This mesh connects with fresh concrete, enhancing the concrete's resistance to shrinkage.

Concrete: Poured over the decking floor and steel mesh. The thickness and concrete grade vary based on project needs, typically using M250 or M300 concrete.

Manufacturing of Deck Sheets

Produced through the cold-rolling method. Depending on project requirements, such as deck type, thickness, length, etc., the rolled sheet is processed to create decking sheets tailored to specifications.

Decking Floor Installation

Deck sheets are accurately placed on the steel beam system and connected to the steel beams using welded studs. Shear studs are applied using specialized welding equipment. A layer of steel mesh is then spread at a distance of 150mm – 200mm, followed by concrete pouring.

Pros and Cons

Advantages:

Lightweight, cost-effective: Creates voids between the steel ribs, reducing the overall weight of the floor and the construction structure. This design minimizes steel structure dimensions and foundation sizes, resulting in significant cost savings.

Easy installation of technical systems: The open spaces beneath the deck allow for easy installation of technical systems, saving space and increasing the structure's overall height.

Accelerates construction progress: Deck sheets are lifted onto steel beams, reducing crane and installation costs. Stacking deck sheets as bundles also saves transportation time and costs.

Design advantages: Superior design with wave heights ranging from 50mm to 75mm. Economical and convenient widths of 1000mm and 870mm. The large wave heights, small reinforcing ribs between waves, and economic widths provide high structural efficiency.

Improved stiffness: Additional secondary waves between the main waves enhance the stiffness of the decking sheet, allowing for larger beam spans with higher safety compared to conventional sheets. The added secondary waves also facilitate easier movement without deforming the sheets during installation.

Aesthetic appeal: The galvanized surface requires no finishing or false ceiling. The bright and durable surface is suitable for various spaces, and it can be kept as is or painted black for an industrial look.

Disadvantages:

Requires precise design calculations: Deck design requires accurate parameters such as floor loads and floor grid dimensions. Engineers need to calculate and select parameters like secondary beam spacing, concrete thickness and grade, mesh specifications, welding stud spacing, and deck sheet thickness.

Wasteful if not optimized: Current deck rolling machines on the market can only roll sheets with a minimum thickness of 1.6mm, leading to limitations in beam span (<4m).

Production limitations: Deck rolling machines can only roll the thickest type of raw material at 1.6mm, resulting in limitations for beam spans <4m (distance between adjacent beams). Beam spans ≥4m do not require additional reinforcement.

Practical Applications

Decking floor solutions apply to all steel frame constructions, multi-story workshops, and various projects including:

High-rise steel frame construction.Offices within workshops.Floors in restaurants, showrooms, and supermarkets.Steel-framed townhouses.

#DeckingFloors #ConstructionTechnology #SteelStructures #FlooringSolutions #DeckSheetDesign #StructuralEfficiency #SteelBeams #ConcreteConstruction #WeldedStuds #TechnicalInstallation #HighTechManufacturing #ConstructionProgress #CostEffectiveDesign #AestheticFlooring #IndustrialDesign #StructuralInnovation #BuildingMaterials #EngineeringAdvancements #FreeTraffic #SEOStrategy #ArchitecturalDesign #ConstructionPros #FlooringAdvantages #BuildingInnovation #ConstructionMaterials #GreenConstruction #SustainableDesign #UrbanDevelopment #ModernArchitecture #StructuralEngineering

Screws for Metal (Sheet) and Wood

Screws for Metal (Sheet) and Wood

We specialize in supplying self-drilling metal and wood screws from North to South. Our customers consistently trust and purchase our high-quality metal screws due to their competitive pricing in the market.

The current range of screw products we offer:

Zinc-coated metal screws.

Stainless steel 304, 201 metal screws.

SEC metal screws.

Dragon-shaped metal screws.

Taiwanese metal screws.

Wood screws.

Self-drilling screws.

Drywall screws.

Description of metal screws:

The screw head designed in a drill shape contacts the surface.

The drill head is hexagonal and is commonly used for drilling the screw into a specific location.

The body is threaded, allowing it to grip deeply into surfaces such as concrete or wood.

The color of metal screws in the market is copper, and they are made of stainless steel or zinc-coated.

Characteristics of metal screws:

Due to the drill-shaped head making contact with the surface and the threaded body, adhesion and grip are excellent. Widely used in construction and interior design, metal screws can penetrate surfaces like iron, steel, concrete, and wood.

Applications of metal screws:

Fastening metal roofs and trusses.

Connecting metal frames.

Installing brackets and supports.

Pricing for metal and wood screws:

No. Specification Unit Price/pack Unit Price/piece Packaging (pieces/pack) Packs/carton

1 12#24-25mm 50,800 254 200 40

2 12#24-40mm 67,400 337 200 25

3 12#24-50mm 72,800 364 200 20

4 12#24-60mm 94,800 474 200 15

5 12#24-75mm 121,000 605 200 13

6 12#24-90mm 144,400 722 200 11

7 12#24-100mm 169,200 846 200 11

8 12#24-120mm 281,800 1,409 200 10

► Request a quotation."

#MetalScrews #WoodScrews #SelfDrillingScrews #ConstructionFasteners #ScrewSuppliers #ZincCoatedScrews #StainlessSteelScrews #SECscrews #DragonShapedScrews #TaiwaneseScrews #DrillHeadDesign #HexagonalHeadScrews #ThreadedBodyScrews #CopperColorScrews #HighQualityFasteners #BuildingMaterials #InteriorDesignFixings #MetalRoofFastening #MetalFrameConnection #BracketInstallation #WoodScrewsSupply #SelfDrillingScrewsOffer #DrywallScrews #ScrewPricing #ConstructionSupplies #MetalRoofing #WoodworkingTools #ScrewsInBulk #CompetitivePricing #RequestAQuotation #BuildingMaterialsSupplier #QualityFasteningProducts #ScrewsForSale #HardwareSupplies

Galvanized threaded rods

Galvanized threaded rods

also known as coupling rods, steel tooth rods, suspension rods, ceiling suspension rods, and cable tray hangers, are extremely important products in construction, especially in the installation of electrical and water systems, air conditioning systems, and fire protection systems in high-rise buildings and factory structures. Galvanized threaded rods are widely used in the construction of civil projects

#ConstructionHardware

#BuildingMaterials

#ScrewsAndFasteners

#MetalScrews

#WoodScrews

#SelfDrillingScrews

#ConstructionSupplies

#BuildingSolutions

#DIYProjects

#HomeImprovement

#ConstructionTools

#RenovationEssentials

#BuildingIndustry

#MetalRoofing

#InteriorDesignFixtures

#FasteningSystems

#ConstructionAccessories

#HardwareStore

#IndustrialSupplies

#ContractorEssentials

Decking Floor Screws, Drilling Capacity 12mm-15mm

Decking Floor Screws, Drilling Capacity 12mm-15mm

Introducing our high-performance Decking Floor Screws with a remarkable drilling capacity ranging from 12mm to 15mm. Crafted under the Stronghold brand, these screws are designed to provide exceptional strength and reliability for various decking floor applications. Whether you're working on construction projects, decking installations, or any other structural endeavors, our screws offer the precision and durability needed for secure fastening. Trust in the quality of our Decking Floor Screws to enhance the stability and longevity of your structures.

#StrongholdDeckingFloorScrews #HighPerformanceFasteners #DeckingConstruction #DrillingPrecision #StructuralReliability #DurableDeckingScrews #SecureFastening #ConstructionExcellence #DeckingInstallation #LongLastingStructures #BuildingStability #PrecisionFasteners #ReliableScrews #DeckingSolutions #ConstructionEssentials #PowerfulDrillingCapacity #DeckingFloorReliability #EnhancedStructuralSupport #QualityConstructionMaterials #IndustrialFastening #BuildingDurability

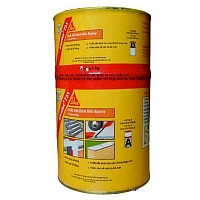

The bonding agent Sikadur 731

Sikadur 731

- It is a type of non-solvent, two-component repair mortar and bonding agent consisting of specially selected high-strength fillers and epoxy resin. It can be used on various materials such as concrete, iron, steel, aluminum, ceramic tiles, wood, glass, epoxy, etc. It is employed for concrete repairs, filling holes and cracks, and surface bonding. Additionally, it serves as an adhesive for steel dowels

#Sikadur731 #EpoxyRepair #ConcreteRestoration #ConstructionAdhesive #HighStrengthBonding #RepairMortar #BuildingMaterials #SurfaceBonding #ConcreteRepair #BuildingSolutions #ConstructionChemicals #EpoxyResin #ConstructionAdhesive #StructuralRepair #HighPerformanceBond #CrackFilling #DurableRepairs #SteelDowelsAdhesive #VersatileBonding #BuildingMaintenance

RAMSET EPCON G5/650ML ADHESIVE - RAMSET STEEL ADHESIVE

-

RAMSET EPCON G5/650ML ADHESIVE - RAMSET STEEL ADHESIVE

Ramset Epcon G5 Steel Adhesive is a high-strength epoxy adhesive suitable for anchoring steel or threaded rods into various substrates such as concrete and natural stone.

Ramset Epcon G5 Steel Adhesive performs well in dry, wet, and underwater drilling conditions.

It is commonly used for:

- Renovating old structures, such as supplementing columns, beams, expanding floors, balconies, etc.

- Connecting steel for pile caps, beam caps, basement floors, beam basement floors into barrett walls in cases where the waiting steel is misaligned or missing.

- Connecting the existing reinforcement of completed elements with the new reinforcement when it is not possible to cast the entire block.

- Managing risks during construction, such as broken steel, incorrectly positioned or inaccessible waiting steel during the construction process."

#RamsetAdhesive

#EpoxyBonding

#SteelAnchoring

#ConstructionAdhesive

#StructuralRenovation

#ConcreteRepair

#HighStrengthAdhesive

#BuildingMaterials

#RenovationProjects

#ConstructionSafety

#AnchorInstallation

#AdhesiveTechnology

#SteelConnection

#ConstructionSolutions

#AdhesivePerformance

#BuildingRenovation

#ConstructionChemicals

#InfrastructureRepair

#EpoxyAdhesive

#StructuralAdhesion

CÁP BỌC NHỰA 3-4-5-6-8MM, ỐC SIẾT CÁP, TĂNG ĐƠ - 3-4-5-6mm PVC-Coated Steel Wire Rope, Anti-Corrosion

Function: Used for hoisting various objects, hanging decorative lights, clotheslines, etc. Manufacturing Materials: The core is made of high-quality carbon steel, and the outer layer is made of flexible PVC plastic. Production Specifications: The core is galvanized steel wire, and it is further processed by adding an outer layer of PVC plastic.

Advantages of PVC-Coated Wire Rope:

The external PVC coating enhances resistance to corrosion, oxidation, especially preventing rust.The plastic coating effectively resists dust and water, making it suitable for environments with salt, acid, and alkali.Excellent tensile strength, pulling, and tightening capabilities.

Applications of PVC-Coated Wire Rope:

With its superior qualities, PVC-coated wire rope is widely used in anchoring and lifting solutions.Construction: Applied in solutions for anchoring steel houses, prefabricated workshops, and tensioning safety nets.Agriculture and Livestock: Utilized in solutions for shading nets in flower gardens, insect nets for clean vegetable cultivation, and supporting banana plants in high-tech cultivation models.Aquaculture: Applied in solutions for anchoring and shading nets in high-tech shrimp ponds.Due to its high aesthetic appeal, PVC-coated wire rope is also commonly used for decorating balconies, stairs, creating trellises for climbing plants, etc.

#PVCWireRope #CoatedSteel #AntiCorrosion #WireRopeSolutions #ConstructionMaterials #AgriculturalNetting #AquacultureGear #SteelWireHoisting #OutdoorDecor #HighTechFarming #RustPrevention #SafetyNets #TensileStrength #PVCProtection #WireRopeApplications #DecorativeLighting #IndustrialMaterials #CableSolutions #RustResistance #FlexibleWire #DurableDesign

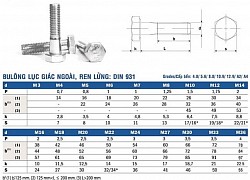

BU LÔNG, Ê CU, LIÊN KẾT - Bolt, Nut, Fastener

Bolts serve various purposes, providing a connection point that can withstand loads such as tension, bending, cutting, and abrasion. They offer long-term stability and facilitate easy disassembly and adjustment of joints without requiring complex technology. Therefore, bolts are applied in numerous industries, including mechanical engineering, assembly, industrial equipment manufacturing, communication infrastructure, bridge construction, and more. Here is an overview of the main sectors that predominantly use and rely on bolts today:

Civil construction and high-rise office building construction.Construction of factories and prefabricated steel structures.Furniture manufacturing and interior design.Domestic use for indoor and garden projects.

Bolts, particularly threaded fasteners, play a crucial role in these industries, providing structural integrity and facilitating the assembly and disassembly of various components

#BoltsAndFasteners #ConstructionHardware #IndustrialEngineering #StructuralConnections #BuildingMaterials #AssemblySolutions #FasteningTechnology #InfrastructureDesign #SteelStructures #InteriorDesign #FurnitureManufacturing #DIYProjects #ConstructionIndustry #EngineeringSolutions #HardwareDesign